Automation is often a defining attribute of CNC machining, revolutionizing the manufacturing landscape. CNC machines operate beneath the steering of computer courses, permitting for specific control and automation of the complete machining process.

With features for instance advanced control systems and high-quality building, toolroom lathes are essential for making intricate components that fulfill stringent specifications.

So as to create complex geometries, for an extended time it was popular to to start with transform workpieces and afterwards finish them on milling machines. DMG MORI was one of several 1st makers to combine both systems in a single workspace.

Kern machines are known for their capacity to manage micro-machining jobs with unbelievable precision.

Complex Geometries and Tight Tolerances: Lots of medical components need complex geometries and extremely tight tolerances. CNC machining supplies the precision important to make these parts reliably and continually.

We've got designed them principally for toolmaking, improvement and exploration and also for training and even further instruction in CNC turning.

Whenever we discuss CNC lathe precision, we’re diving into little measurements that make an enormous big difference. Consider a human hair. It’s slim, right? Now, split it into fifty items. The precision we explore in CNC lathes is even finer than that. Let’s split Get started this down into easier phrases.

Analytical cookies are used to understand how visitors interact with the website. These cookies enable provide information on metrics the number of visitors, bounce rate, visitors source, etcetera. Advertisement Ad

The spindles of the high precision lathe are oil cooled. They are also integrated, which suggests they don't have belts or pulleys, leading to a lot less noise and an improved surface finish. All this boosts accuracy and cuts down machining time.

Reliability can be a essential attribute of CNC machines. These machines are created to work constantly and continuously, producing them highly reputable in meeting production calls for.

CNC machining is essential for industries that require high precision and effective manufacturing processes.

Bar loaders assure a constant provide of material to ensure that machine operate times are maximized. Several robotic-supported automation solutions is often used to machine chuck components.

The way forward for CNC machining is poised to revolutionize the manufacturing industry with advanced tactics and enhanced automation. Just one notable trend is the rising popularity of multi-axis machines with much more than 3 axes.

When you’re in the marketplace for a high precision CNC lathe, aiming for machines that marry top-tier accuracy with reliability is very important. Look no additional to get a concise rundown:

Hailie Jade Scott Mathers Then & Now!

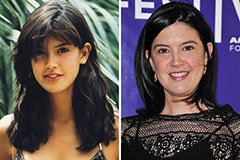

Hailie Jade Scott Mathers Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!